Welcome to the ultimate guide to perfect binding, the go-to bookbinding technique for high-quality print publications. Whether you’re an aspiring author, a self-publisher, or a professional in the publishing industry, this comprehensive guide is designed to equip you with all the knowledge and tips you need to produce exceptional perfect bound books. From understanding the concept of perfect binding to selecting the best materials and service providers in Australia, we’ve got you covered. Let’s dive in!

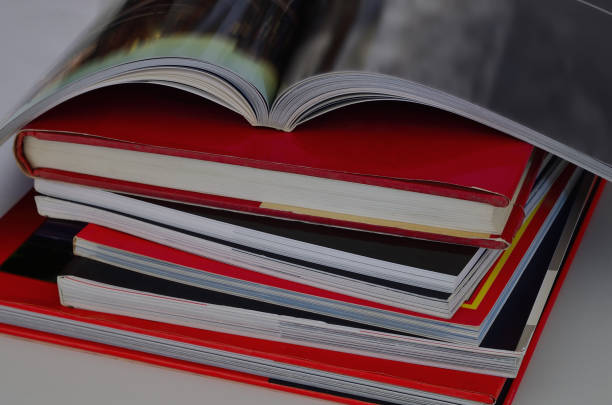

Perfect binding is a popular Book Printing method that has gained widespread recognition for its clean and polished look. This technique utilizes adhesive to bind the pages together, creating a professional and seamless finish. In modern bookmaking, perfect binding plays a significant role in delivering high-quality print publications.

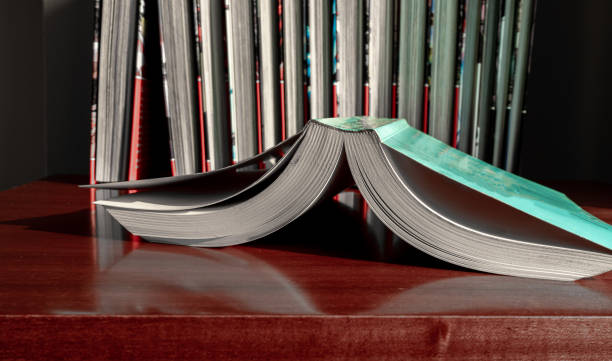

So, how does perfect binding work? The process involves applying adhesive to the book’s spine area, adhering the internal pages together as a single unit. This method is well-suited for paperback books and magazines, offering durability and flexibility. By utilizing perfect binding, bookmakers can achieve a sleek appearance while maintaining the integrity of the book’s content.

The advantages of perfect binding are manifold. It provides a cost-effective solution for publishing high-volume books, making it a popular choice for large-scale production. Additionally, perfect binding allows for easy customization, enabling bookmakers to incorporate unique design elements and branding elements into their projects. Moreover, the adhesive used in perfect binding provides a secure hold, ensuring the longevity of the book.

In modern bookmaking, perfect binding is embraced for its versatility and efficiency. It caters to various genres, including novels, catalogs, marketing materials, and art books. With its streamlined process and professional results, perfect binding allows bookmakers to deliver visually appealing publications that captivate readers.

To provide a comprehensive understanding of perfect binding, the next section will compare it with other binding techniques, shedding light on its unique features and advantages.

When it comes to choosing the right binding technique for your printed publications, it’s important to consider the options available and how they impact the final product. Two commonly used binding methods, perfect binding and saddle stitch binding, each have their own set of advantages and limitations. Additionally, case binding offers a distinct aesthetic appeal for special projects. In this section, we will compare these binding techniques to highlight the reasons why perfect binding stands out as a preferred choice for paperback binding.

Saddle Stitch Binding:

Saddle stitch binding involves stapling the pages together along the fold, creating a booklet-like appearance. While this method is often used for magazines, brochures, and small booklets, it does have its limitations. Saddle Stitching is not suitable for thick or heavy books as the staples may not hold the pages securely and could result in damage or pages falling out over time.

Case Binding:

Case binding, also known as hardcover binding, provides durability and an elegant appearance. This method involves attaching the pages to a rigid case, typically made of cardboard or chipboard, which is then covered with a decorative material. Case binding is well-suited for prestigious projects like coffee table books or special editions. However, it may not be the ideal choice for paperback binding due to the additional cost, weight, and complexity involved in the process.

Perfect Binding:

Perfect binding, on the other hand, combines the advantages of professional appearance, durability, and flexibility while keeping the cost reasonable. Using adhesive, the pages are securely bonded to the spine, creating a strong and seamless binding. This method allows for smooth lay-flat reading and is well-suited for thick books or publications with a higher page count. Perfect binding provides a clean and modern look, making it a popular choice for Hard and Soft Cover Books that desire a professional finish.

When comparing these binding techniques, it becomes clear that perfect binding offers a balance of durability, aesthetics, and affordability. This makes it an ideal choice for paperback binding, particularly for print publications that require a high-quality finish.

In this section, we will provide you with a comprehensive overview of the perfect binding process. We will take you through the journey, from understanding the concept of perfect binding to the creation of a creased spine. By the end of this section, you will have a clear understanding of the step-by-step process involved in perfect binding.

Through this step-by-step process, perfect binding transforms loose pages into a professional, high-quality book. From concept to creased spine, every stage is essential in creating a visually appealing and functional finished product.

The selection of paper and cover types is crucial in perfect binding as it directly impacts the overall quality and appearance of the finished book. From paper quality and weight to cover design considerations and material choices, every decision plays a significant role in creating a visually appealing and durable perfect bound book.

When selecting paper for perfect bound books, it’s important to consider the quality of the paper. Opt for high-quality options that are acid-free and archival-grade, ensuring the longevity of the book. The weight of the paper is also crucial, as it affects the durability and perceived value of the book. Choose a weight that balances sturdiness and flexibility, keeping in mind the intended purpose and target audience of the book.

The cover of a perfect bound book serves as its first impression. It is essential to carefully consider the design elements to align with the content and target market. Utilizing professional graphic design services can help create an eye-catching cover that effectively communicates the essence of the book. Elements such as typography, imagery, color schemes, and finishes should be chosen thoughtfully to enhance the overall aesthetic appeal.

For the cover of a perfect bound book, a range of material options is available. Common choices include cardstock, art paper, linen, leather, or even custom materials to suit specific themes or branding requirements. The material not only adds visual appeal but also contributes to the durability and tactile experience of the book. The selection should align with the desired look and feel of the finished product.

| Paper and Cover Type | Paper Quality | Paper Weight (GSM) | Cover Material | Cover Design Possibilities |

|---|---|---|---|---|

| Coated Gloss/Matte Paper | High-quality, smooth finish | 80-200 | Cardstock, art paper | Excellent for vibrant colors and sharp images |

| Uncoated Paper | Natural, textured finish | 60-120 | Cardstock, linen | Great for a rustic or classic aesthetic |

| Faux Leather | N/A | N/A | Leather, synthetic leather | Elegant and luxurious feel |

| Fabric | N/A | N/A | Linen, cotton | Perfect for a tactile, high-end look |

Adhesives play a crucial role in perfect binding, ensuring the durability and integrity of the final product. Different types of glue can be used in perfect binding, each with its own advantages and characteristics.

Polyurethane Reactive (PUR) Glue: One of the most popular adhesives used in perfect binding is polyurethane reactive (PUR) glue. PUR glue offers exceptional strength and flexibility, making it ideal for binding books that will undergo frequent use and handling. It has superior resistance to temperature, moisture, and chemicals, ensuring that the bound pages stay intact even in harsh conditions. PUR glue also provides excellent adhesion to a wide range of paper stocks, including coated, glossy, and recycled papers.

Hot Melt Glue: Another common type of adhesive used in perfect binding is hot melt glue. Hot melt glue is a thermoplastic adhesive that is melted and applied in a molten state to bind the pages together. It offers fast setting times, allowing for efficient production processes. Hot melt glue provides good initial bond strength and is suitable for binding applications that require minimal exposure to temperature extremes and moisture.

Cold Glue: Cold glue, also known as liquid glue or wet glue, is another option for perfect binding. Cold glue is applied in a liquid state and dries to create a strong and permanent bond. It is commonly used in manual or semi-automatic binding machines. Cold glue offers excellent penetration into the paper fibers, resulting in a strong and durable bond. However, it may require longer drying times compared to other adhesive options.

When choosing the right adhesive for perfect binding, consider the specific requirements of your project. If durability and resistance to harsh conditions are essential, polyurethane reactive (PUR) glue may be the best choice. For fast production processes and applications with minimal exposure to extreme conditions, hot melt glue can be a suitable option. Cold glue is ideal for manual or semi-automatic binding processes that allow for longer drying times.

Understanding the different glue types in perfect binding enables you to make informed decisions, ensuring the quality and longevity of your bound books.

Perfect binding involves a meticulous step-by-step process to ensure a professional and high-quality finish. Let’s explore each stage of the binding process:

Following these steps will result in a professionally bound book with a clean and polished appearance. Perfect binding is a popular choice for a wide range of print publications, offering a seamless and durable binding solution.

| Advantages | Challenges |

|---|---|

| – Clean and professional finish | – Lack of lay-flat capability |

| – Suitable for large print runs | – Potential wear and tear on the spine |

| – Affordable option for paperback books | |

| – Customizable cover design options |

Perfect binding offers a range of advantages that make it a popular choice for bookbinding. Firstly, it is an affordable option, making it ideal for high-volume production of print publications. The process is efficient and cost-effective, allowing for the creation of high-quality books at a reasonable price.

Furthermore, perfect binding provides customization options, allowing for the inclusion of unique cover designs, graphics, and logos. This versatility makes it appealing to authors, publishers, and businesses looking to create personalized print materials.

However, there are also a few challenges associated with perfect binding. One of the limitations is the lack of lay-flat capability. Unlike other binding methods like wire-o or spiral binding, perfect-bound books cannot lay completely flat when open. This can sometimes be inconvenient for readers who prefer a more user-friendly experience.

Another challenge is the potential wear and tear on the spine of perfect-bound books. With frequent use, the adhesive may weaken, causing pages to come loose or detach from the spine. Although this can be mitigated by using high-quality adhesives (PUR Binding) and proper handling, it is still a consideration to keep in mind when choosing perfect binding for your publications. Ensure PUR method is used to avoid this.

| Advantages of Perfect Binding | Challenges of Perfect Binding |

|---|---|

| Affordability Customization options Efficient and cost-effective | Lack of lay-flat capability Potential wear and tear on the spine |

In conclusion, perfect binding offers a high-quality and professional solution for bookbinding needs. Throughout this guide, we have explored the popular techniques of perfect binding, including its role in modern bookmaking, a comparison with other binding techniques, the step-by-step process, advantages, challenges, and top service providers in Australia.

When considering the choice of binding method for your publication, perfect binding is ideal for various types of print publications, such as magazines, catalogs, brochures, and even paperback books. Its clean and polished finish adds an elegant touch to any project, making it an excellent choice for those seeking a sophisticated look.

Embracing the elegance of perfect bound books not only enhances your brand’s image but also ensures durability and affordability. It provides a professional appearance that impresses readers and stands the test of time. So, when it comes to choosing the perfect binding method, consider the advantages it offers, such as customization options and cost-effectiveness, while also being aware of the challenges, such as the lack of lay-flat capability.

In conclusion, perfect binding is a versatile and reliable option that combines functionality and aesthetics, offering a sleek and sophisticated presentation for your printed materials. Whether you are a business looking to create impactful marketing collateral, or an author publishing your latest novel, perfect bound books are a timeless choice that will leave a lasting impression.

Perfect binding is a bookbinding technique that uses adhesive to securely bind the pages together, creating a clean and professional-looking finished product.

Perfect binding provides a polished and professional look to books, making it a preferred choice for many modern bookmakers.

Perfect binding is compared to other common techniques like saddle stitch binding and case binding, highlighting its advantages as the preferred choice for paperback binding.

The perfect binding process involves several steps, starting from the concept of perfect binding to the creation of a creased spine. It will outline the step-by-step process involved in perfect binding, giving readers a clear understanding of how it is done.

When selecting paper and cover types for perfect bound books, it is important to consider factors such as paper quality, weight, cover design considerations, and material choices.

Polyurethane reactive (PUR) glue is a commonly used adhesive in perfect binding due to its advantages. Additionally, hot melt glue and cold glue are other options that can be suitable for specific projects.

The step-by-step process of perfect binding involves preparing the pages and covers, applying the adhesive, and trimming the finished book.

The advantages of perfect binding include affordability and customization options. However, challenges include the lack of lay-flat capability and potential wear and tear on the spine.

Copyright © 2024 Five Horizons. All Rights Reserved.